The #KSD – KRAFFT Steel Dryer

“… over the past years, KRAFFT Walzen has delivered around 300 #KSD – KRAFFT Steel Dryers direct to paper mills and OEMs in the North American market.

We can fulfil all demands in respect of dimensions (433+” face length), speed (6.600+ fps) and operation pressure (200+ psi). This allows us to support projects on a short-term notice and have the full competence for large volume projects with big dimensions and volumes.

We have a strong believe, that our #KSD with its unique and proven design has set the benchmark for paper drying …. “

The Lightest

- Less drive power

- faster heat-rampup time

- higher avaiability of your line

- more paper

The Stiffest

- Less movement or travel in bearings

- More stable run, which supports smooth run of the fabric

The most Sustainable

- best drying performance

- maximum paper width

- highest efficiency

- more paper

The benchmark product for paper drying

- In the past year around 300 high pressure drying system were delivered to the USA or are under order

- Face lengths above 12.000 mm / 472"

- Steam pressure up to 20 bars / 290 psi

- Constant and lower wall thicknesses

- Homogeneous temperature distribution

- More web width in consisting machine frame

- No risk of leakage

- Customised adaption of diameter to any intermediate size

- European DGRL and US-ASME Standard and ML China Code

- KSD-HTG (High Temperature Gradient)

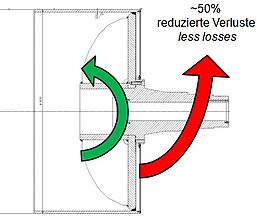

The #ESD for #KSD - Energy and Safety Device

By default, the #KSD is equipped with an #ESD - Energy&Safety Device.

The design was originally intended to meet machine guidelines, but has been further developed for a number of years to reduce radiation losses at the cylinder head sides.

Without this cover, this loss via the heads can be estimated at several 10 kg of steam per hour and cylinder, depending on the product and the speed. And that's expensive high-pressure steam.

With the #ESD we reduce these losses on the cylinder faces significantly. The energy of the high-pressure steam remains in the cylinder.

Can or do you still want to afford to lose several 10kg steam per hour per cylinder?

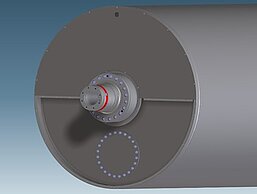

The KRAFFT #KSD - "Still the Greatest"

"... the steel drying cylinder, from the #KSD series (KRAFFT Steel Dryer), put into operation at Papierfabik Palm, Wörth (Germany) in April 2018, was the the biggest steel drying cylinder in these days. In the meantime this masterpiece was overruled in facelength.

But: The #KSD at Palm remains to be the benchmark and is "Still the Greatest", but no more the biggest ..."

The dimensions of the #KSD are:

- Diameter 1.830 mm

- Face length 11.150 mm

- Design speed 1.800 m/min

The #KSD

from KRAFFT Walzen

The KRAFFT Steel Dryer as a benchmark product for the future of paper drying.

The #WSR - Wire

from KRAFFT Walzen

The Wire Stabilization Roll from the product group of passive bending balancing rolls (Center Supported).

The #QAC - Quiet-as-Carbon

from KRAFFT Walzen

The Reel Spool

from KRAFFT Walzen

Highly dynamic balanced reel spools with over 100 tons of paper weight.

The Winder and Reel Drums

from KRAFFT Walzen

Highly dynamic balanced in the system with cover, grooving, perforation and bearings.

The #TFC

from KRAFFT Walzen

The Thermo Function Cylinder provides the process energy for the treatment of goods.

The #LCS - Life Cycle Sensor

from KRAFFT Walzen

The #LCS is a roller-attached sensor for the determination of usage data of rollers, especially reel-spools