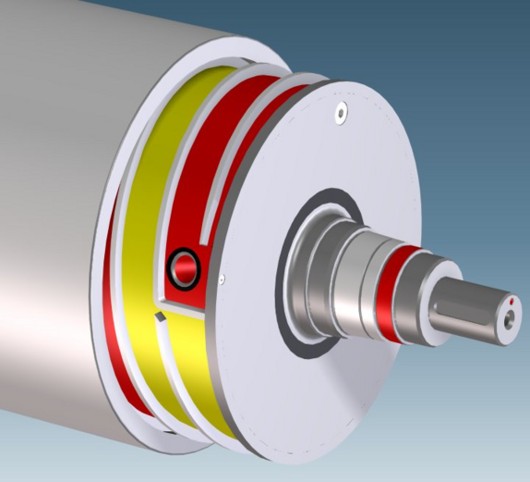

The #TFC – Thermo Function Cylinder

The #TFC - Thermo Function Cylinder is the synergy of the properties for

the goods handling of the paper web,

from the product areas paper and non-paper

The aim at this point is to provide process heat, in order to finish the

product in conjunction with an additive.

- Double jacket design

- Process temperatures of up to 300 ° C

- Diameter range from approx. 1,000 mm

- Temperature accuracy over the path length up to +/- 1 ° C

- Media guidance by conducting spirals optimized for low pressure loss

- Adjustment of the desired / required heat profiles

- Optional including equipment such as inlet pipe, sealing head and bearings

- Optional with coating (e.g., ceramic, nickel, chrome)

The #KSD

from KRAFFT Walzen

The KRAFFT Steel Dryer as a benchmark product for the future of paper drying.

The #WSR - Wire

from KRAFFT Walzen

The Wire Stabilization Roll from the product group of passive bending balancing rolls (Center Supported).

The #QAC - Quiet-as-Carbon

from KRAFFT Walzen

The Reel Spool

from KRAFFT Walzen

Highly dynamic balanced reel spools with over 100 tons of paper weight.

The Winder and Reel Drums

from KRAFFT Walzen

Highly dynamic balanced in the system with cover, grooving, perforation and bearings.

The #TFC

from KRAFFT Walzen

The Thermo Function Cylinder provides the process energy for the treatment of goods.

The #LCS - Life Cycle Sensor

from KRAFFT Walzen

The #LCS is a roller-attached sensor for the determination of usage data of rollers, especially reel-spools