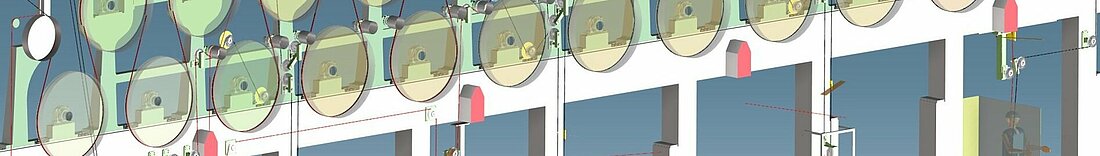

KRAFFT Engineering – Roller and Cylinder Dryer (Fluid)

Water- or oil-heated roller or cylinder dryers for:

- Woven and

- Non-Woven products

To achieve different finishing properties

- Textile

- Nonwovens

- Membrane

Features/Performance data:

- Energy saving and efficient drying method

- Wrinkle-free, gentle and low-tension drying method

- Optimum temperature accuracy through targeted media guidance within the rollers

- Drive of drying cylinders with frequency-controlled individual drives

- Oil or water heating

- Energy recovery

- Rollers with pull sensors

- Turn Key system

Options:

- Insulation housing with humidity-control

- CKS insulation housing with air conditioning system

- Energy recovery

- Integrated IR dryer

- Residual moisture measurement

- Cooling cylinder, integrated or in separate frame

- Heating medium hot water or thermal oil

- One or two-sided drying

Roll surfaces:

- Anti-stick coatings (PTFE, FEP, etc.)

- Chromed

- Stainless steel (1.4301, 1.4404, 1.4462)

- Stone or belt grinded

.

Data sheet - KRAFFT Engineering Roller and Cylinder Dryer (Fluid)

Selected engineering projects of KRAFFT

KRAFFT Engineering – Rope Guide System

As a complete system with tensioners, pulleys and guider. "Classic" or with rodless pneumatic cylinders

KRAFFT Engineering - Flaker

Flaker in in-dip technology for use in the medical or food industry.

KRAFFT Engineering Non-Woven Calender

Nonwoven Calender with up to 7m facelength

KRAFFT Engineering - Thermofixing and Stretching Machines

Optional with drying. For technical textiles to achieve different finishing properties.

KRAFFT Engineering – Roller and Cylinder Dryer (Steam)

Steam-heated roller or cylinder dryers for woven and non-woven products to achieve different finishing properties.

KRAFFT Engineering – Roller and Cylinder Dryer (Fluid)

Water- or oil-heated roller or cylinder dryers for woven and non-woven products to achieve different finishing properties.