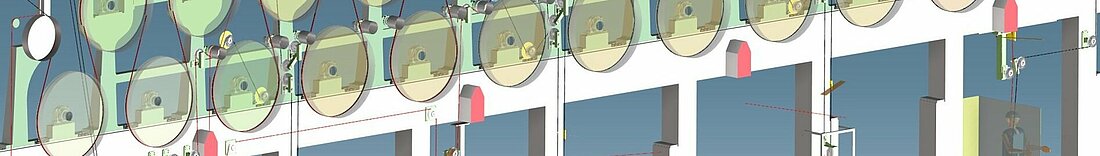

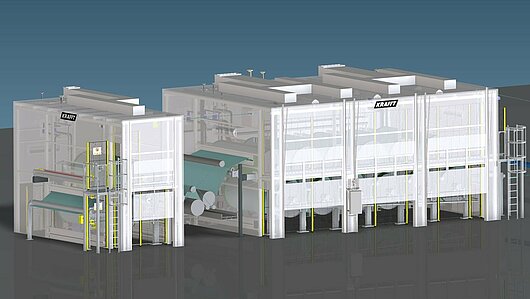

KRAFFT Engineering – Roller and Cylinder Dryer (Steam)

Roller and Cylinder Dryer for:

- Classic woven fabric

- Technical Textiles

- Nonwovens

- Filaments

Features/Performance:

- Energy efficient and efficient drying

- Wrinkle-free, gentle and low-tension drying method

- Optimum temperature accuracy thanks to modern thermo compressor technology

- Drive the drying cylinders with frequency-controlled single drives

- Steam heated with thermos compressor technology

- Turn-key system with electrical control

Options:

- CKS insulation housing and energy recovery

- Feeding machine at machine speed

- Bypassing of the dryer group with towed or driven guide rollers

- Division of the drying group into temperature and drive control groups

- Grease or circulating oil lubrication

- Residual moisture measurement

- Material and process-adapted surface coatings

- Cooling cylinder, integrated or in separate frame

- One or two-sided drying

Data sheet - KRAFFT Engineering Roller and Cylinder Dryer (Steam)

Selected engineering projects of KRAFFT Engineering

KRAFFT Engineering – Rope Guide System

As a complete system with tensioners, pulleys and guider. "Classic" or with rodless pneumatic cylinders

KRAFFT Engineering - Flaker

Flaker in in-dip technology for use in the medical or food industry.

KRAFFT Engineering Non-Woven Calender

Nonwoven Calender with up to 7m facelength

KRAFFT Engineering - Thermofixing and Stretching Machines

Optional with drying. For technical textiles to achieve different finishing properties.

KRAFFT Engineering – Roller and Cylinder Dryer (Steam)

Steam-heated roller or cylinder dryers for woven and non-woven products to achieve different finishing properties.

KRAFFT Engineering – Roller and Cylinder Dryer (Fluid)

Water- or oil-heated roller or cylinder dryers for woven and non-woven products to achieve different finishing properties.