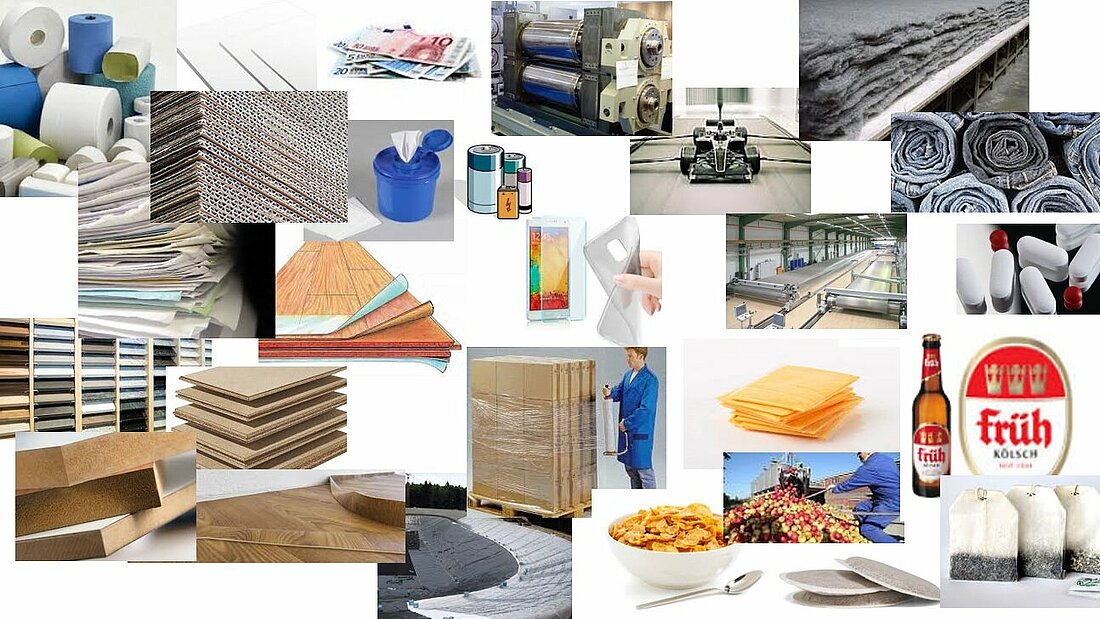

Applications - Made with KRAFFT

We tend to take the products we use in our daily lives for granted. We rarely consider the effort required to manufacture and distribute these products.

Our teams produce the rollers and machines for high-tech products in order to achieve sophisticated products for discerning end customers.

We are very closely connected to the products you need and use every day. How does one describe the variety of products around the "abstract product roller that looks so simple and round"?

The catalysts for this success are our trainees. Over 15 of our current 145 employees are learning on-the-job at KRAFFT. At the kick-off event of the new group of trainees in August, we introduced the company to the "newcomers". The first question was: "What are such rolls actually used for?" Instead of providing an abstract description, we propose presenting the final products in order to explain our core products.

We would like to take you on a journey: a weekend of discovering products that can be manufactured thanks to KRAFFT.

Made with KRAFFT – A different view!

Let's start: We are sitting at breakfast, reading the newspaper and my wife and I are planning what I should do this weekend.

The newspaper:

Paper is KRAFFT’s classic product. Since the founding of our company in 1870, we have been closely associated with the paper industry. Düren is still one of the strongholds of the paper industry in Germany, and even boasts a fascinating paper museum. That's the reason why machine manufacturers then settled around Düren. We were there from the beginning and today serve all continents from our location in Düren. KRAFFT is one of the few full-range suppliers of rolls for the paper industry - KRAFFT Rollers. However, a major change is taking place. While graphic papers and newspaper printing are in decline due to changing living conditions, tissue or household and sanitary paper (toilet paper, kitchen rolls, etc.) as well as packaging papers are being bought more. The Internet and the smartphone have become driving forces for two products: changing reading habits and online trading.

Another coffee and off to the car. Oh… the coffee pad is also one of the products.

The carpet in my car is made using calender rollers too.

For the manufacture of batteries, we provide compactor rollers and the rubber compounds of tyres are also calendered on KRAFFT rollers.

My car was certainly also subjected to a test-run using a drum from KRAFFT Turning Technologies with a diameter of up to 5 meters.

At the last inspection the filters were exchanged, these also contain a particular type of paper.

The way to the hardware store leads us past an open pit mine. Belt drums from KRAFFT Pulleys are used to equip conveyor belts, which then transport raw materials, ores, and also coal and bulk materials for all kinds for processing.

A new road is being built right next door. Geotextiles are used for the construction of our roads, not only for drainage, but also to protect it from wear and tear.

The hardware store is an Eldorado for products "Made with KRAFFT". When examining the kitchen worktops, the structure of the worktops can be easily recognized as being made up of chipboard core or chipboard panels, several layers of craft paper, Decorative paper and overlay.

My spontaneous comment: "All layers could have at some point come into contact with a KRAFFT roller." We continue and go past the wallpaper section. Paper again. Slightly further on, we can see the plasterboard on offer. Both the manufacturer of the paper or cardboard and the boards are among our customers.

Garden department: The thick pond liners also run through "our” double-jacket rollers. Moving on past the floor coverings: Heated rollers, double-jacket, of course, for the production and coating of laminate flooring.

The wood department. I need MDF panels for a practical shelf. These plates or chipboard, are made on really "big things". "Peripherally drilled drums, sometimes with diameters of over 4 m".

Motorsport is on TV in the electronics department and the station is currently explaining the concept of a wind tunnel: the rollers on which the "moving floors" are running are ours. Incidentally, the optically high-precision foils of televisions or smartphones could have been produced on casting rolls by KRAFFT rollers.

Many of the products are packed in beautiful boxes. We produce rolls for the production of the cardboard and for printing presses we produce pressure cylinders that then produce the printing plates.

Plastic sheeting is the second major area of packaging materials, a very diverse market. In sheet extrusion, the sheeting is stretched and extended among other things, which you can find as super-thin plastic film in packaging, but also as advanced forms of film for the highest product requirements (hygienic, chemical etc.) and even increasingly in batteries for e-mobility as so-called BFS

And it continues: Our neighbour is currently renovating his house with a thermal insulation system. The reinforcing layer is made using a fabric (glass fibre fabric) among other things. The abrasive paper of the grinder with which it processes the garage door is stabilized by a thermosetting machine from KRAFFT Engineering.

Cash is paid using paper notes at the cash desk. We also produce rolls for the production of banknote paper. If only we had built a bigger basement!

Off home now - I still have a lot of plans and I’m getting thirsty so time for an apple juice. You’ve guessed it already: We also make rolls for juice presses. Hungry? Of course, a cheeseburger. In the food industry, processed cheese runs over stainless steel rollers. A chocolate bar is also always good: We are not only represented both in the production of chocolate and in the production of chocolate bars, but also in the food-safe packaging with printed films.

In the parking lot there are some amazing motorcycles, which, people say, are no longer comfortable for people of my age. Parts of the motorcycle and its paneling are made of carbon fibre. The large-scale plants for the pyrolysis process for the production of carbon fibre rovings are equipped with rolls from us.

On the way home I drive past the container terminal: rope drums for large cranes or freight lifts are just more of our products. Today, the wind turbine park nearby is producing a great deal of energy: There is a giant rotor in the nacelle in which we at KRAFFT Turning Technologies play a small but important role …. at the bottom of the substation, the insulators are made of high-strength glass fibre reinforced plastic. We make the winding spindles for these.

Let’s continue on the highway. Ah, there’s one of our impressive green/yellow vehicles and trucks with our branding coming towards me - KRAFFT Services on tour, and outside of normal business hours. Thanks, colleagues, I suppose you are bringing our products to customers as part of our 24/7 emergency service.

Finally at home. The parcel service has been here and has delivered a gift box well packaged in corrugated cardboard -forming rolls are another one of our products. If the corrugated base paper was also dried by our highly efficient KSDs , it would be a dream!

Time to clean the car: I like to use pre-impregnated fleece cloths. The rolls for the production of these cloths are sold in the "non-woven" product group. In this car, I have treated myself to great seat covers from „Alcantara“. This is a highly refined micro fibre fabric, which is produced by a carding process using carding rolls. As less refined or compacted fabric, you will find them used for example for the padding of jackets in the textile industry. Anyway, our dog is always happy when his mistress or master dries him with these microfiber cloths after a walk followed by a shower - he is not picky.

You can get sweaty palms when confronted by so many KRAFFT products, no problem, just wipe them dry on your trousers. We offer complete cylinder drying systems with control technology and housing for the drying of woven textiles - KRAFFT Engineering. Incidentally, my jeans are torn from so much work or "destroyed" as you seem to say now.

Today I don’t have to go to the landfill site. Too bad, because I would have seen landfill films on large areas, a durable plastic waterproofing membrane with a smooth or textured surface for sealing, which we made on calender rolls.

It’s evening and I have a pain in my back- something I like to complain about to my wife almost as much as I like to list my terrible symptoms when I have a cold. A painkiller? KRAFFT Engineering provides Flakers to the pharmaceutical industry, which are used in the production of painkillers. My wife then nurses me with a kinesiological tape or physio tape that one of our customers makes. The Flaker also makes corn flakes, hence the name.

A beer would go down well now. Yeast dryers for breweries from the product group of KRAFFT drying cylinders. The label on the bottle is of course also made of paper.

Back to the trainees: "You will be working on all of these products. Rollers, rotationally symmetrical objects and machines for a wide variety of applications, purposes and process steps that need to be constantly improved over and over again, because the requirements of our customers and end customers (that includes you too) are constantly growing - Made with KRAFFT. "